Navigating the Globe of Fasteners and Machining: Techniques for Accuracy and Speed

In the elaborate realm of fasteners and machining, the mission for precision and speed is a perpetual difficulty that demands precise interest to information and calculated preparation. From recognizing the varied variety of bolt kinds to choosing optimum materials that can stand up to extensive needs, each step in the process plays a critical role in achieving the desired outcome.

Understanding Bolt Kind

When selecting bolts for a task, recognizing the various types readily available is important for ensuring ideal efficiency and reliability. Bolts are utilized with nuts to hold products together, while screws are flexible bolts that can be used with or without a nut, depending on the application. Washers are necessary for distributing the load of the fastener and protecting against damage to the material being secured.

Picking the Right Materials

Understanding the value of picking the right products is critical in making sure the optimum efficiency and reliability of the chosen fastener types went over previously. When it pertains to bolts and machining applications, the product option plays an essential function in figuring out the total toughness, resilience, corrosion resistance, and compatibility with the designated atmosphere. Different materials use differing homes that can dramatically influence the efficiency of the bolts.

Usual products utilized for bolts consist of steel, stainless steel, brass, titanium, and light weight aluminum, each having its one-of-a-kind toughness and weak points. Steel is renowned for its high stamina and toughness, making it ideal for a vast array of applications. Stainless-steel uses exceptional rust resistance, ideal for environments vulnerable to moisture and chemicals. Light weight aluminum is light-weight and corrosion-resistant, making it appropriate for applications where weight reduction is crucial. Brass is typically selected for its aesthetic allure and outstanding conductivity. Titanium is known for its remarkable strength-to-weight ratio, making it excellent for high-performance applications. Choosing the best material includes thinking about factors such as stamina requirements, environmental conditions, and spending plan constraints to ensure the preferred performance and long life of the bolts.

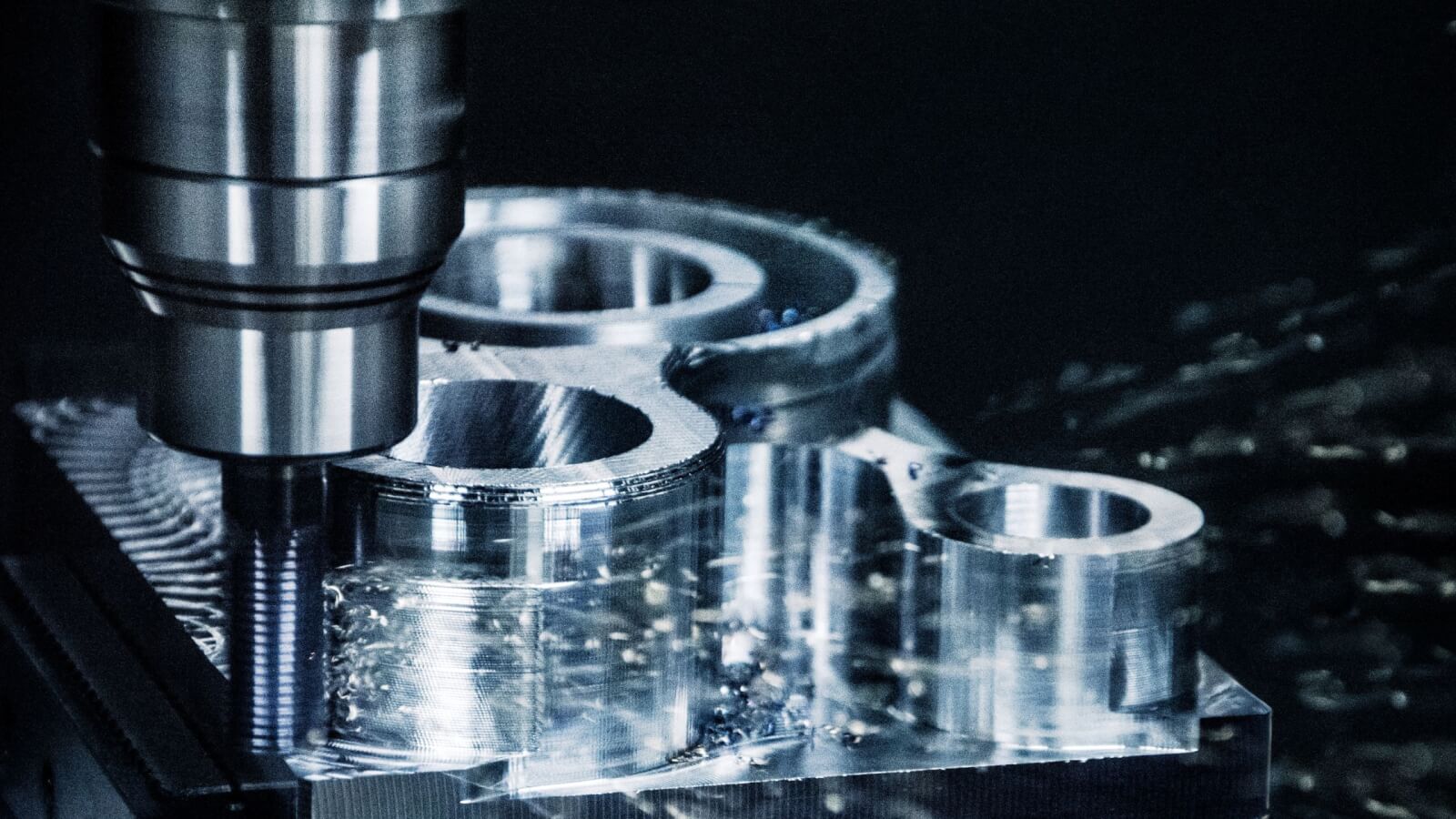

Accuracy Machining Techniques

Along with CNC machining, other precision strategies like grinding, turning, milling, and exploration play vital functions in bolt production. Grinding assists attain fine surface coatings and limited dimensional tolerances, while transforming is commonly Learn More Here used to create cylindrical parts with specific sizes. Milling and drilling procedures are vital for forming and producing holes in fasteners, guaranteeing they fulfill exact specs and feature appropriately.

Enhancing Speed and Performance

To optimize fastener manufacturing procedures, it is essential to improve procedures and apply efficient techniques that match accuracy machining strategies. One key technique for improving rate and performance is the execution of lean production concepts. By reducing waste and focusing on continuous enhancement, lean methods assist get rid of traffic jams and enhance process. Furthermore, buying automation innovations can substantially improve manufacturing speed. Automated systems can deal with repeated tasks with precision and speed, allowing employees to concentrate on even more complicated and value-added activities. Adopting Just-In-Time (JIT) inventory management can additionally boost performance by making certain that the appropriate products are offered at the correct time, reducing excess inventory and reducing preparations. Cultivating a culture of collaboration and interaction among group participants can enhance total effectiveness by promoting openness, analytical, and innovation. By incorporating these techniques, manufacturers can attain a balance in between speed and precision, eventually boosting their affordable side in the fastener market.

Quality Assurance Actions

Applying extensive high quality control measures is critical in making certain the integrity and uniformity of fastener products in the production process. Fasteners and Machining. Quality control measures incorporate different stages, beginning from the selection of raw materials to the final assessment of the finished bolts. This includes assessing variables such as material make-up, strength, and sturdiness to find assure that the fasteners fulfill industry requirements.

Normal calibration of devices and equipment is crucial to maintain consistency in manufacturing and ensure that fasteners fulfill the required tolerances. Applying strict procedures for recognizing and dealing with issues or non-conformities is crucial in protecting against substandard items from entering the market. By developing a thorough quality control framework, producers can promote the reputation of their brand and provide fasteners that satisfy the highest possible criteria of performance and resilience.

Verdict

In the detailed realm of fasteners and machining, the quest for precision and speed is a perpetual challenge that requires thorough attention to information and critical preparation. When it comes to bolts and machining applications, the product option plays a crucial role in determining the overall strength, durability, deterioration resistance, and compatibility with the desired setting. Accuracy machining entails numerous sophisticated techniques that guarantee the tight resistances and requirements needed for fasteners.In addition to CNC machining, various other precision techniques like grinding, turning, milling, and exploration play essential functions in fastener production.To maximize fastener production procedures, it is necessary to enhance operations and execute efficient approaches that match precision machining strategies.